At Eck Plastic Arts, we understand the importance of parts made with quality and excellence, done the right way, and delivered on time. We have been producing quality, reliable, custom plastic part fabrication for all industries since 1949. We know what we are doing. We are confident in our ability to produce amazing parts for our customers. We understand how disappointing parts and slow production timeline can smother an entire job or project. This exact feeling of aggravation, disappointment, and overall frustration is what motivates us to excellence of quality in the parts we produce, people we hire, and the junction to live out our Mission statement day in and day out.

Let us take you through our four main services we offer. We know our services can add important value to your next project!

Injection Molding

There’s a lot of different ways to get your plastic parts made. Injection Molding is unique in itself! It is an ideal process for manufacturing parts with an assortment of details. Do you need parts with detailed features? Parts with complex geometry? Have a large quantity of parts you need? We have you covered! Every single one of our production molds are guaranteed while we have them in our possession.

First, injection molding takes resin which are little granular pellets and then adds pressure and heat to inject them into a mold, which makes a net shape. Well how did we do that? Good questions. The first principle we follow is that all plastic needs to be dried. Keyboards, cell phones – and plastic components have moisture in them. It is our job to get that moisture out. If we were to just bring the temperature up, it would cause it to off gas, giving us a brittle part. We don’t want that and neither do you! This is why injection molding is an incredible process. First we dry the material, and the material then gets conveyed directly from the dryer into the feed throat of the machine. This is where the resin drops in. The feed throat then drops down into the barrel of the machine. The barrel is essentially just a hydraulic cylinder with a screw or auger on the inside, that is constantly turning and grinding and plasticing. By “plasticising” we mean that it is being brought to a semi-liquid state, and pushing it forward in that barrel. From here, the plastic is forced in and travels into the mold.

This brings us to the full-frame production mold. This is where some awesome magic happens! Every 20 seconds we have net parts being produced through our processes. This is so important to note because of molds and the prices they generally cost. Molds can cost anywhere between $5,000 to $100,000. Of course it depends on what you are making, cavitation, and other various factors.

Here is the magic that we make at Eck Plastic Arts- if you get a part every 20 seconds, your piece price is going to be significantly less expensive. The mold is able to pay for itself super quickly! This is how we are able to take an extensive look at the project you have, and accurately decide how to build the mold you need while keeping it low cost and of great value to you.

Some benefits to Injection Molding from us include: insert Molding, over molding, undercuts, fine tolerances, custom colors, internal/external Threads and of course competitive pricing. You own your mold after as well! Check out our website for more details, or to get a quote today!

One thing that we are great at doing is taking a look at your project on the finance end, with the goal of strategizing. We ask, “How do we want to build this mold so that we can keep the cost down as much as possible”. We do this with the goal of producing the absolute most cost effective part for you. Check out our Youtube channel for a step by step breakdown on Injection Molding.

Thermoforming

Thermoforming is the process of heating a thermoplastic sheet and applying a force to form it into or over a mold. We love thermoforming because of its low tooling and engineering costs, as well as its amazing fast turnaround time. Time is a vital resource, and we know time is money- especially when it comes to completing projects.

Thermoforming is good for low volume runs and perfect for larger parts with thin walls (covers, guards, windows, trays). We love the versatility of thermoforming and the fact that almost any thermoplastic can be thermoformed. We love to be able to understand your project and discuss things like polymer cost, temperature of processing, crystallinity of the resin, and the degree of difficulty of extruding the sheet. We discuss these things because of the wide variances in the cost of the project depending on these details. Hint – we want to be able to produce parts for you, at the lowest possible price! Our ability to understand and adapt to your needs is a byproduct of our commitment to our customers since 1949. Check out some more benefits on our website.

Here at Eck Plastic Arts we offer two types of Thermoforming services:

Vacuum Forming

Curved Windows

Vacuum Forming has low engineering costs and quick turnaround time. These two things make it very ideal for prototype development and low-volume production for small and large product designs. Incredible high quality, reduced lead times and design flexibility and a few reasons why we love vacuum forming as an option for our customers. We are able to offer a large variety of surface textures and printed features due to the fact that the cosmetic side of the part is on the non-mold surface of the given sheet. This could mean awesome things for your next project! Fun fact: Vacuum Forming is the most popular method used of Thermoforming!

Curved Windows has some awesome advantages itself! Advantages include exceptional quality, no tooling cost, no tooling marks on the window, shorter lead times, and personalized customer service. Fun fact: Eck Plastic Arts has developed a proprietary process that puts a radius into sheet plastic without requiring tooling. Another excellent way to show that here at Eck Plastics we are constantly striving to develop better processes to produce better parts for our customers. This incredible process removes tooling costs, delivery lead times- all while maximizing the ascetics of your window! An amazing option offered to you from Eck Plastic Arts.

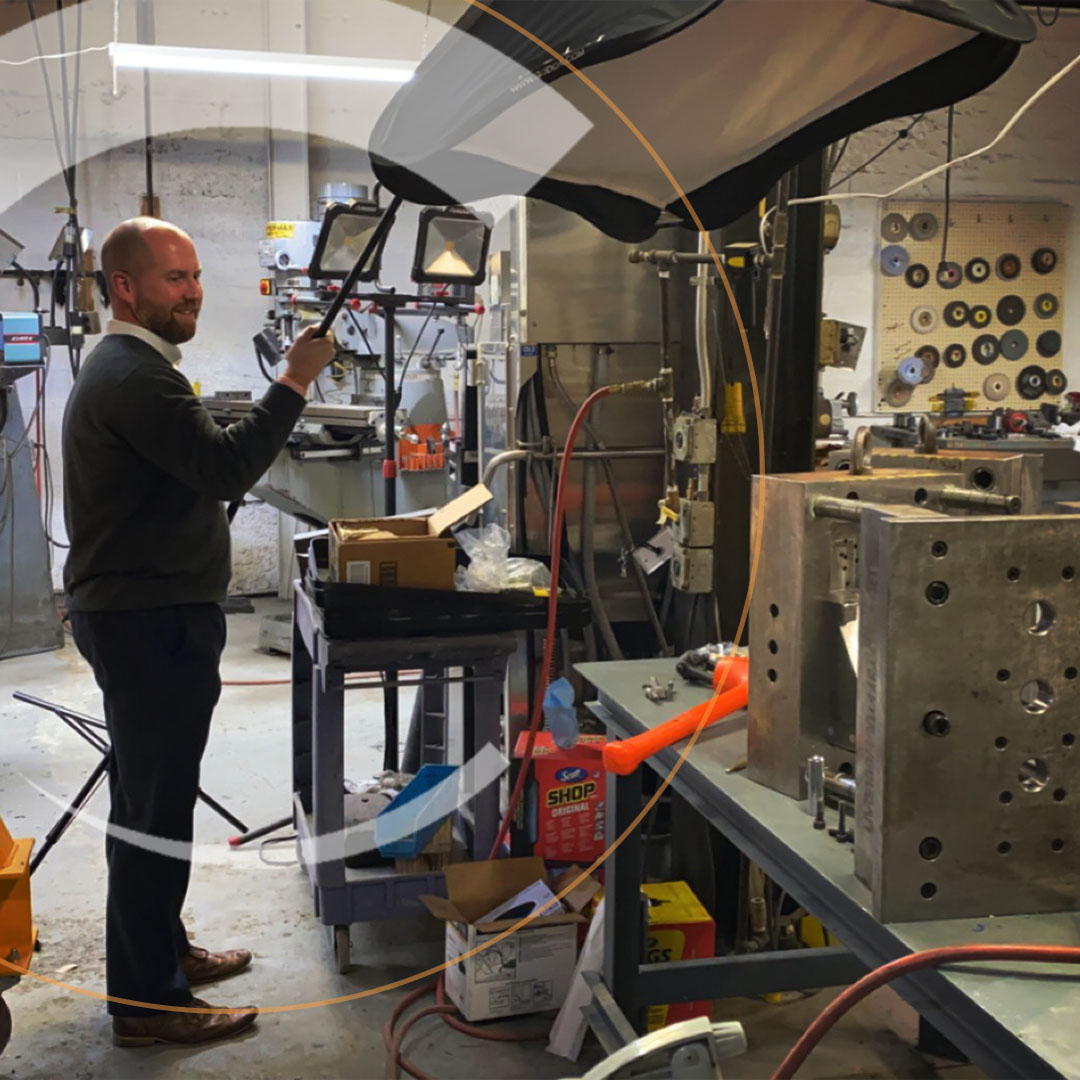

Plastic Fabrication

We are incredibly proud to be able to say that Eck Plastic Arts is a leader in plastic fabrication when it comes to all things profile cutting, forming, and assembly of plastic sheets and bar stock. Are you starting to feel our mission seep through the words of this blog post? We love our work, our craft, and our ability to gain excellency through the mission of quality. We are able to guarantee unmatched attention to detail and quality from simple covers and enclosures – all the way to precision control panels and electronic lighting assemblies.

Our heavy duty hydraulic brake press is equipped with CNC controlled back-gauges, and die lengths up to 96 inches. Equipment like this excites us and energizes us in creating amazing parts for our customers. We strive to produce excellence and that shows through our specialization in complex assembly processes. Chemical bonding? We have it. Ultrasonic Welding? Have that too. How about ESD shielded electronic assemblies? You already know- that is a yes from us.

Plastic fabrication at Eck Plastic Arts stands out for many reasons. There are no minimum quantities required, we want to help you with any size project you have going on. We offer competitive pricing, free consultation for manufacturability and static dissipative materials. Check out our website for more information, or a quote!

Product Finishing Operations / Assembly

We hope you’ve learned at this point in the blog post that we love to meet the needs of our customers with excellence and value. We have been in the plastic parts business long enough to know that delivering quality parts oftentimes requires more than injection molding to finish a project.

One thing that really excites us is that when you work with Eck Plastic Arts- there is no need to contract multiple suppliers for finishing and assembly services. We take the hassle out of finishing a project by offering these finishing and assembly services, because we know the value of having quality parts from beginning of the project, to the end.

We know and love the satisfaction that comes with getting the job done.We currently offer CNC and manual machining of inserts and plastic parts, painting, hot stamping, pad printing, sonic welding, multi-component assemblies, and customer packaging. Check out our website for further information and resources!

RECAP

We wanted to share with you a reminder of your services because we know our services can tremendously add value to any project you have. Every detail of your project is important, your work is important, everything you do is important! This is what drives us to achieve mastery level of the four services we have. We love making great parts, but we love serving people who do great things even more.

We hope we were able to give a refresher course on the services that are at the core of our skill set. Our four services operate in harmony. Combine them with hard work and diligence from our team – you get incredible quality, every single time.

The Eck Plastic Arts Partnership Promise: Hire and train good people. Execute precise processes. Deliver quality Parts. It is what we believe, do, and deliver. We look forward to long-term partnerships and are excited to get going on your parts!