Process of heating a thermoplastic sheet and applying a force to form it into or over a mold

Benefits of the Thermoforming Process

The most advantageous aspects of thermoforming are its low tooling and engineering costs as well as its fast turnaround time.

- Lower to no tooling cost

- Good for low volume runs

- Quick turnaround times

- Perfect for larger parts with thin walls. (Covers, guards, windows, trays)

Almost any thermoplastic can be thermoformed. As with any manufacturing process, there are wide variances in the cost of different materials due to the polymer cost, temperature of processing, crystallinity of the resin, or, in general, the degree of difficulty of extruding the sheet.

The ECK Plastic Arts Advantage to Vacuum Forming

Due to its low engineering costs and fast turnaround time, vacuum forming is ideal for prototype development and low-volume production for both small and large product designs.

- Low Cost Tooling

- No Minimum Quantities

- Highest Quality

- Design Flexibility

- Reduced Lead Times

- Consistent Result

- Customized Solutions

- Delivering Secondary Operations, as Needed

Since the cosmetic side of the part is on the non-mold surface of the sheet, a wide variety of surface textures or printed features are available.

VACUUM FORMING IS THE MOST WIDELY USED METHOD OF THERMOFORMING

This process includes moving either a male or female mold into a hot sheet and using a vacuum to remove the air trapped between the sheet and the mold. This allows atmospheric pressure (14.7 p.s.i) to move the heated sheet into contact with the mold. Typical applications include non-critical appearance covers, dunnage trays and internal covers.

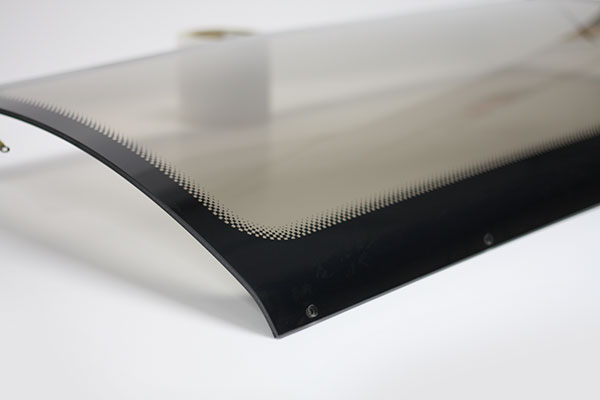

The ECK Plastic Arts Advantage to Curved WIndows

- No tooling cost

- No tooling marks on the window

- Exceptional quality

- Personalized customer service

- Shorter lead times

ECK PLASTIC ARTS HAS DEVELOPED A PROPRIETARY PROCESS

Eck Plastic Arts has developed a proprietary process to put a radius into sheet plastic without requiring tooling. This process will remove your tooling costs, delivery lead times, all while maximizing the ascetics of your window.

Injection Molding

Process that creates plastic objects by injecting molten plastic into a mold

Injection Molding

Process that creates plastic objects by injecting molten plastic into a mold

Thermoforming

Process of heating a thermoplastic sheet and applying a force to form it into or over a mold

Thermoforming

Process of heating a thermoplastic sheet and applying a force to form it into or over a mold

Plastic Fabrication

From advice on how to design for manufacturing, or assembly of plastic products

Plastic Fabrication

From advice on how to design for manufacturing, or assembly of plastic products

Product Finishing Operations

Delivering quality plastic parts may require more, and Eck Plastic Arts is ready to complete your project!

Product Finishing Operations

Delivering quality plastic parts may require more, and Eck Plastic Arts is ready to complete your project!

The Eck Plastic Arts Partnership Promise:

Hire and train good PEOPLE. Execute precise PROCESSES. Deliver quality PARTS.

We believe through our quality PEOPLE and the focus on continually improved PROCESSES we deliver the highest quality plastic PARTS ensuring your confidence in a long-term partnership.